Projects

Innovative, Multi-disciplined, Involved

The various projects highlighted here with exception to one have been entirely conducted solely through my own will and ambition. My strive to become a more accomplished, well rounded, and experienced engineer encouraged the development of these personal projects, encompassing everything from research, design, manufacturing, electrical engineering, and computer programming. The success of every project is a direct result of personal self-taught skills, problem solving through root-cause analysis and countless hours of dedicated work.

Podex

Hexapod Robot

A hexapod robot controlled with a graphical UI and wearable arm control. Uses PWM servos and a Raspberry Pi as its motherboard. Fully 3D printed hardware and entirely self-assembled, soldered, and programmed.

Sector

6DOF Robotic Arm

A 6 DOF robotic arm controlled through a GUI. A self-driven project made almost entirely from additive manufacturing processes. Uses inverse kinematic algorithms for geometrical movements.

Arm Remote

Gyro Control Interface

Designed and intended to be a wearable untethered remote for the hexapod robot, Podex. Uses buttons, joysticks and accelerometers as input and transmits through the standalone serial-communication wifi network.

3D Light Cube

LED Light Display

This project is best simplified as a glorified night light. Using 216 LED's, each LED can to a certain extent be individually controlled with the Arduino Nano. The system is battery powered and has a 3 button interface.

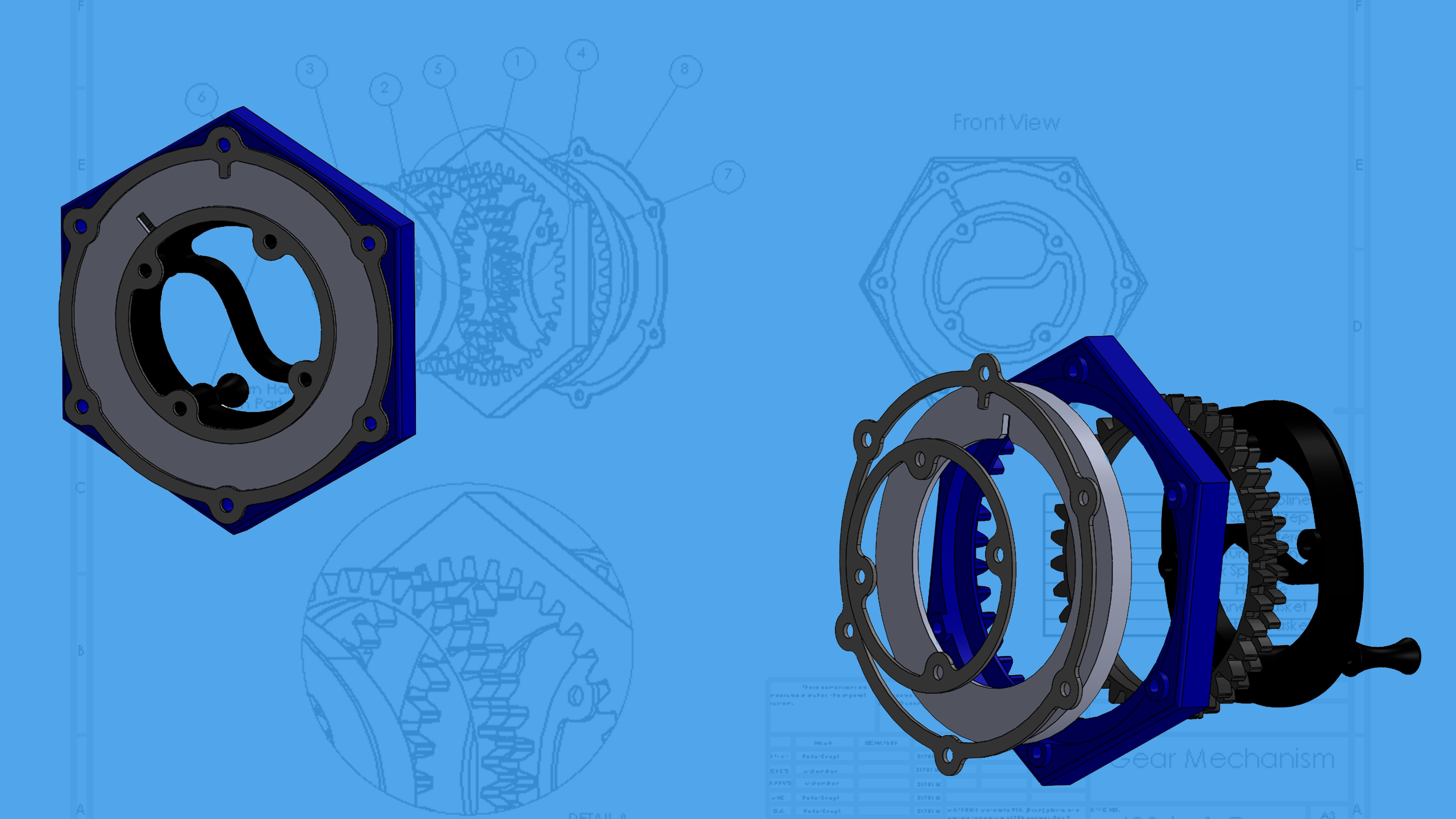

Gear Box

400-1 Gear Reduction

This fully 3D printed assembly converts 400 rotations of motion into 1 singular rotation through an unconventional method. Two harmonic drives offset by one tooth, creates this drastic gear ratio.

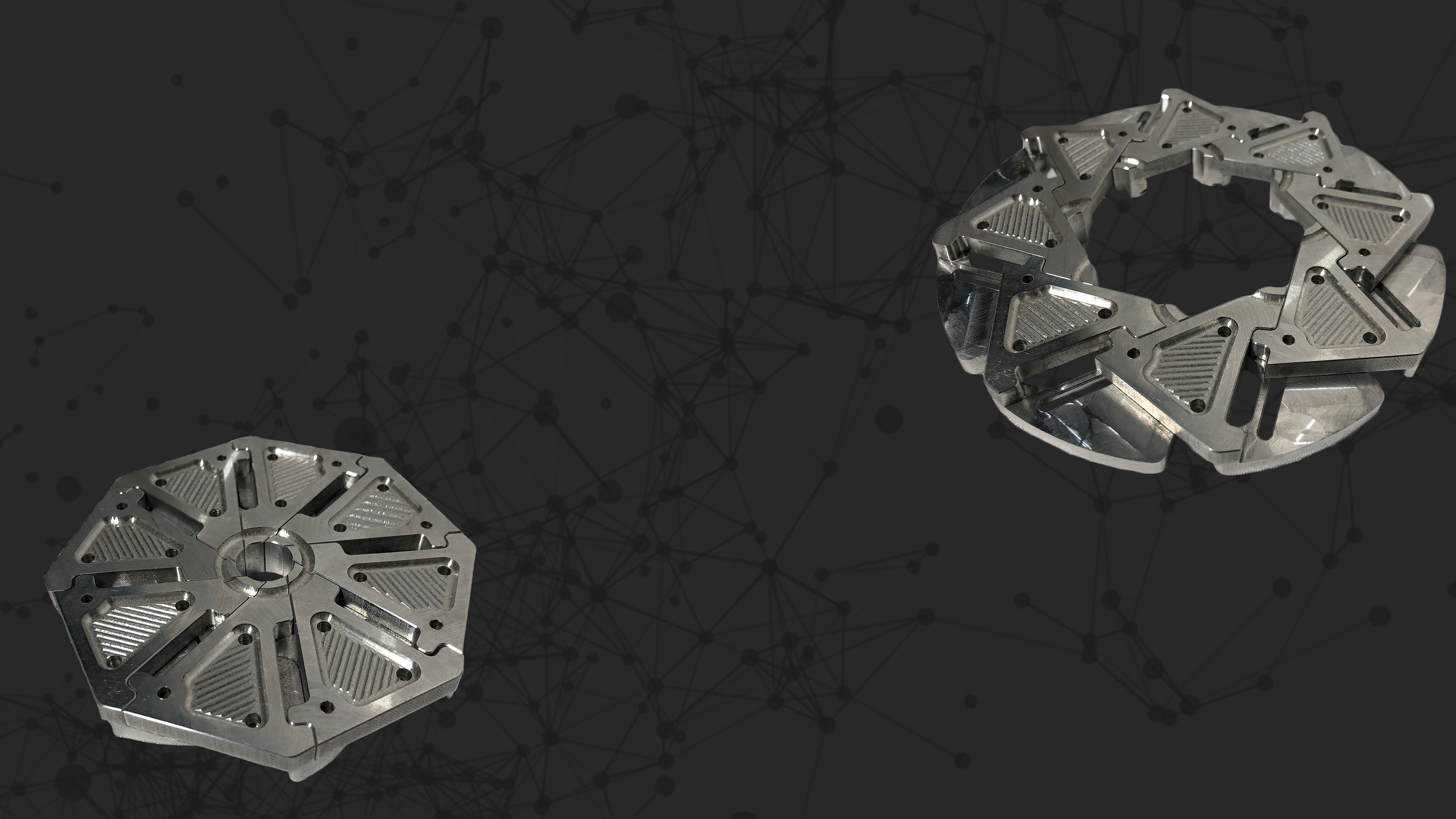

Hexconic

Manufactured Assembly

This project is a CNC manufactured assembly of 8 identical components, fabricated on a 3 axis mill. The purpose for conducting this project was to mature my skills in the CNC and CAM fields of engineering.

3D Printed Parts

Miscellaneous Projects

This page highlights a few various projects I designed and fabricated through the additive manufacturing process. These projects display the extent of my skills in CAD through complex geometries.

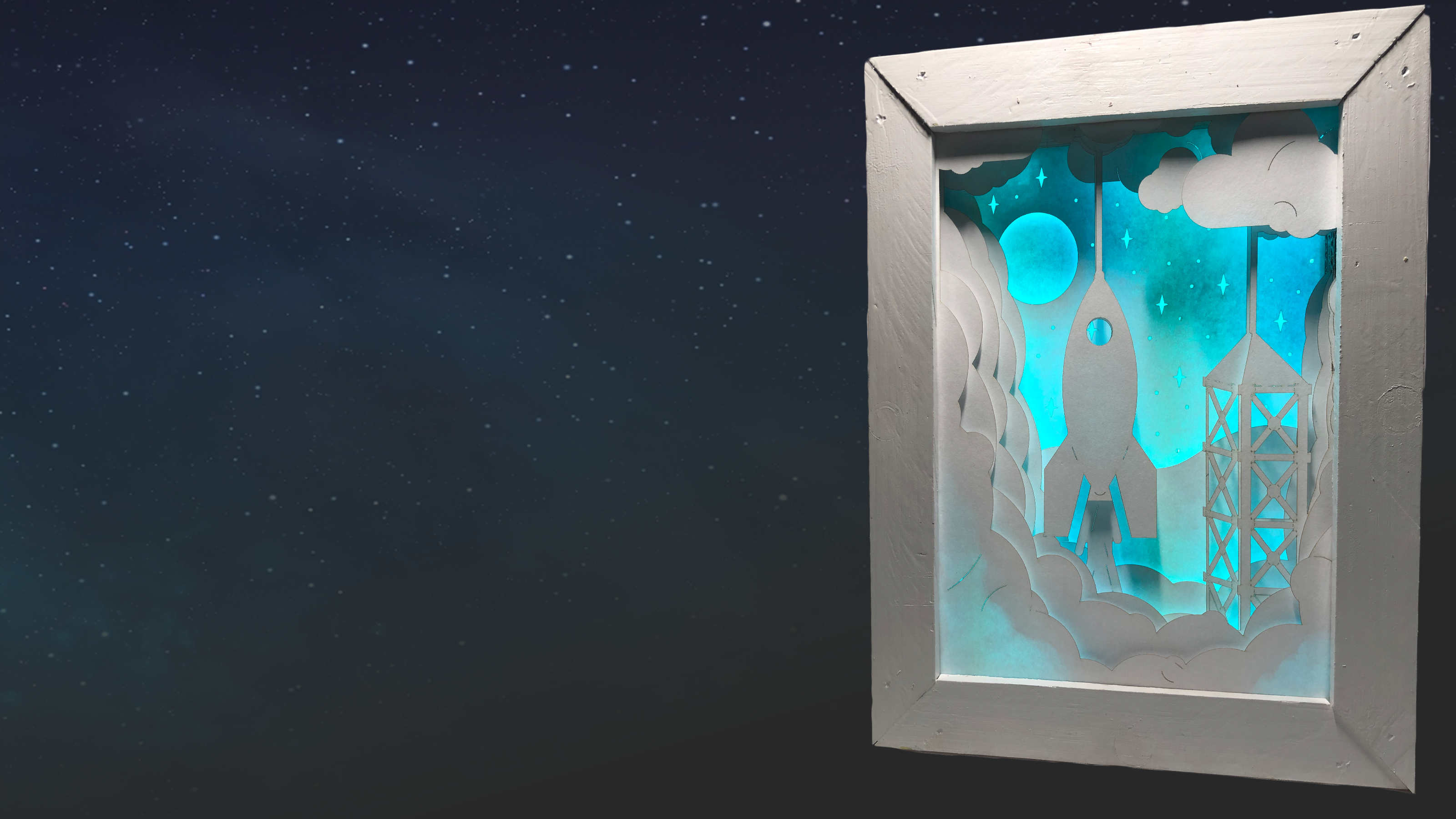

3D Lamp

Laser Cut Light

The surface appearance result is the entirety of this project. After seeing a similar idea on an ad, I decided to fabricate myself one. Design, artistic touches, and CAD expertise were crucial in its success.

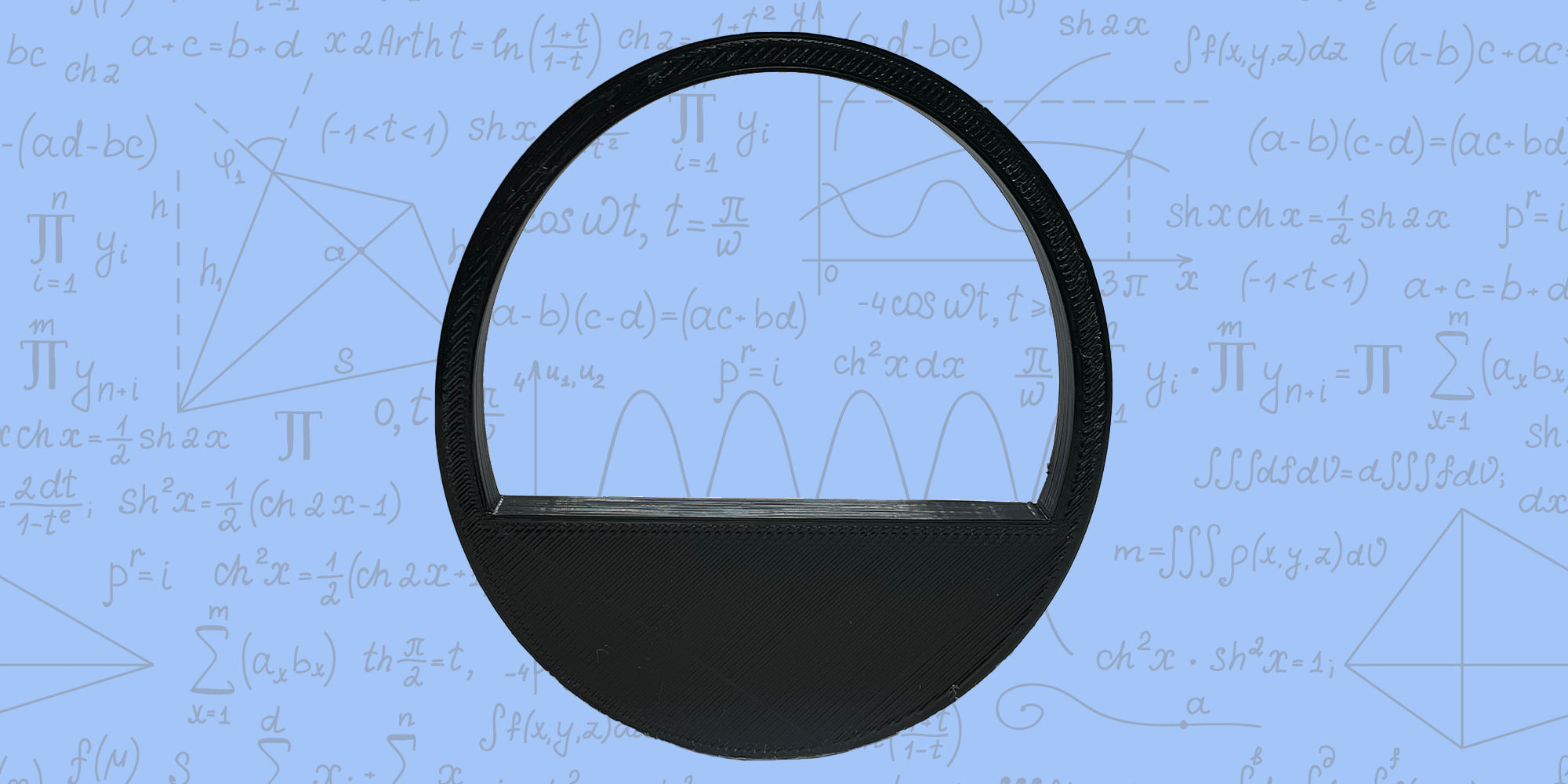

Roly-Poly Toy

Self-Centering Project

This project is the only personal project in my entire portfolio required from educational studies and not through my own merit. The result of this project however was a very sophisticated object.